The world is set to become a safer place, thanks to breakthrough research.

In this post 9/11 era, having your bags swabbed at the airport is just another part of life. The swab is used to detect bomb residue and uncover terrorists before they strike.

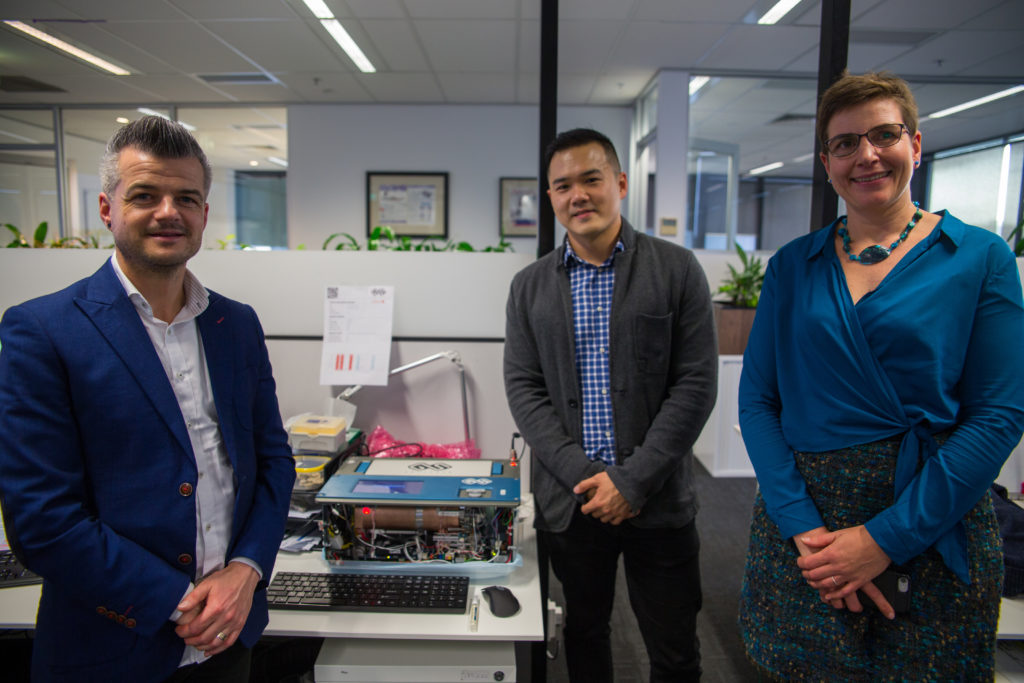

The testing net is about to be cast much wider, however, thanks to contributions made by Deakin researchers Professor Rosanne Guijt, Associate Professor Robert Shellie and Dr Ryan Nai, who contributed to this work when working at the University of Tasmania.

The world-leading research team partnered with Melbourne company Grey Innovation, translating their findings into a detection device.

Using cutting edge technology, the team of scientists and engineers has significantly extended security testing capacity to reveal chemical residues from home-made bombs (containing fertiliser and other inorganic compounds), which are now the most common type of terrorist explosive device.

The research team’s cross-disciplinary skills, including analytical chemistry and fluid dynamics, combined with the engineering and commercialisation capacity at the Grey Innovation Group, led to the development of GreyScan, the world’s first portable “explosive trace detector” for inorganic compounds.

As well as airports around the world, the device could readily be adopted in non-aviation areas such as screening of cargo, mail or rail passengers, or for public security at embassies, commercial premises and major events.

“Today, it is believed that the greatest risk to homeland security comes from home-grown terrorists and home-made explosives,” said Jefferson Harcourt, Director of GreyScan.

“GreyScan outperforms by up to 10 times the current standards sought by the US Government for airport security.”

The project is helping to put Australian research on the map. It has won one of the nation’s science “Oscars,” the Australian Museum Eureka awards (2019 Defence Science and Technology Prize for Outstanding Science in Safeguarding Australia).

The research team is led by UTAS’s Michael Breadmore, Professor of Analytical Chemistry, and has been investigating inorganic compound analysis for over 10 years.

“It is fantastic to see our fundamental research findings contribute to the real world in this way,” said Professor Guijt, who currently leads Deakin’s Smart Sensing team in the Centre for Rural and Regional Futures.

“Like researchers everywhere, we want to protect people. If we can improve safety at many events around the world, it will be a great achievement.”

What is microfluidics?

Developed over the past 30 years, the field of microfluidics is revolutionising the way laboratory experiments, including chemical analysis, are conducted.

Most people are unaware that fluids behave differently (but predictably) at the microscale, but owing to this predictability small, portable devices can provide high precision (bio)chemical data analysis from a tiny drop of sample.

“Using the high level of fluidic control, the inorganic compounds can be sampled and analysed in solution, providing a unique advantage over other portable techniques that rely on target volatility.

By their chemical nature, the inorganic explosives are not volatile (not easily vaporised) and therefore not suitable for traditional gas-based sensing,” said Professor Guijt.

Brilliant minds, a large island and a tiny chip…

The research story began at the University of Tasmania over 10 years ago.

The eminent team at the Australian Centre for Research on Separation Science (ACROSS) at UTAS was approached by the Office of the Prime Minister and Cabinet to investigate the potential of miniaturised chemical analysis systems for security purposes.

This led to seven grants over the following years, including funding from the US military and the Australian Research Council, and an expanding team.

Three of the researchers sought to extend their research at Deakin.

“The engineering expertise and facilities at Deakin are world-class. They will be vital for the development of new applications of this technology, such as environmental monitoring,” said Professor Guijt.

Once the separation chemistry and fluid handling were under control, a joint venture with Melbourne-based technology commercialisation company Grey Innovation led to the development and commercialisation of GreyScan.

GreyScan Director, Jefferson Harcourt noted that the company is working closely with the US-based regulators: TSA (Transportation Security Administration) and IATA (International Air Transport Association) and expects international aviation regulations to change to include inorganic explosive trace detectors.

“GreyScan is the only solution available to integrate into the current installed base of equipment deployed in airports around the Globe,” said Harcourt. “We’re ready to go. We have distribution agreements in multiple regions that service 25 countries and have already sold to government agencies here and abroad.”

“One day I hope to be at the airport and to be tested by one of our own instruments,” added Professor Guijt.

In fact, her hope is highly likely to become a reality in the near future.

Claire Whiteley

Staff writer